Interlacing Jets for POY/FDY spinning process

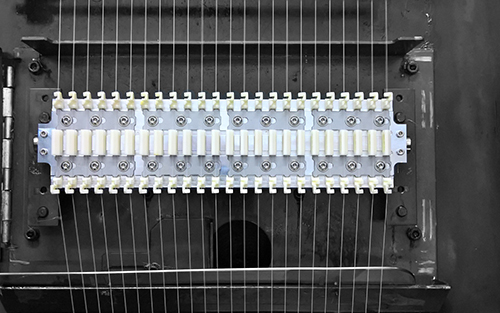

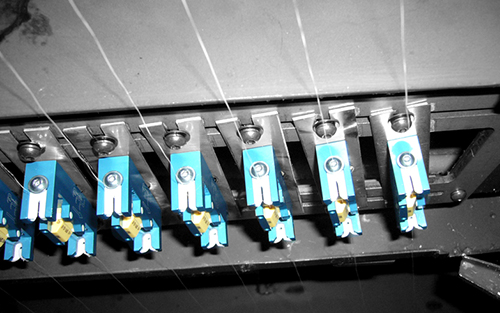

SPF interlacing jets

SPF jet, single

SPF jet, twin

SPF technology

The design enables the application of single jets, as well as multi thread jets, to all conceivable numbers of thread lines and yarn end separations.

The easy quick exchange system of the jet inserts allows a simple and safe maintenance.

The sophisticated geometry and surface character within the interlacing zone guarantee an excellent interlacing performance concerning the high requirement of the composed knot regularity.

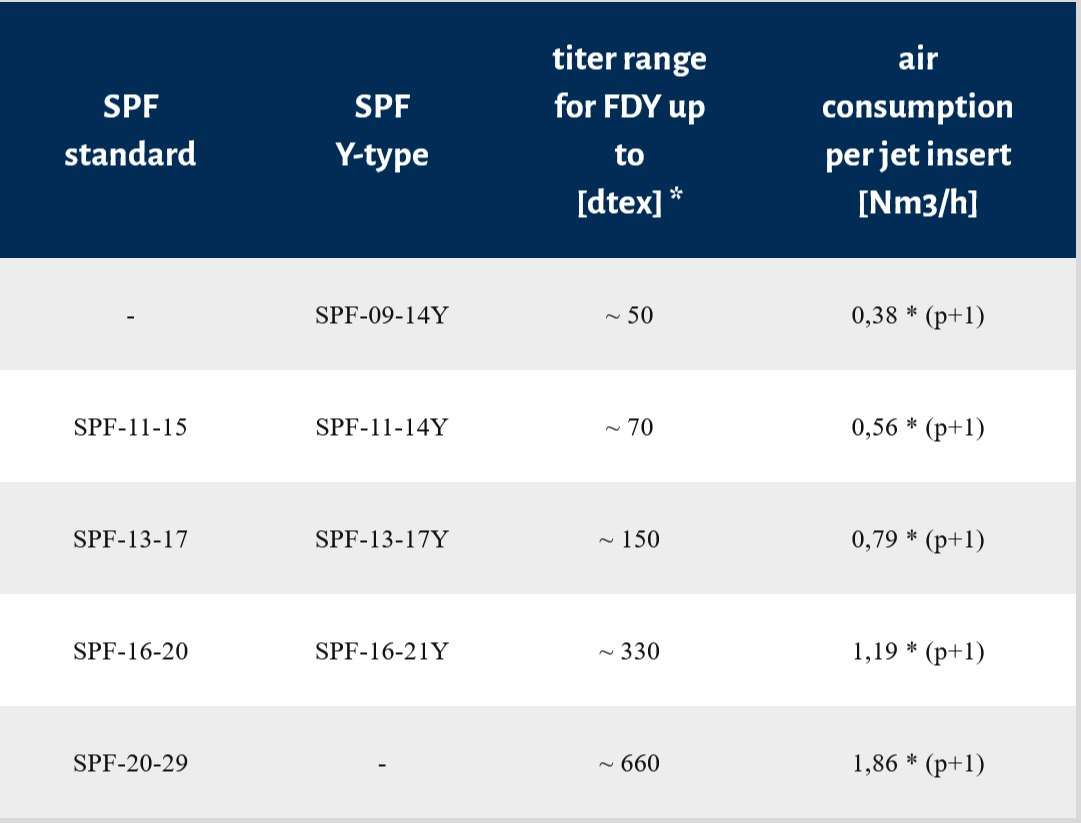

SPF standard | SPF Y-type | titer range | air consumption |

|---|---|---|---|

- | SPF-09-14Y | ~ 50 | 0,38 * (p+1) |

SPF-11-15 | SPF-11-14Y | ~ 70 | 0,56 * (p+1) |

SPF-13-17 | SPF-13-17Y | ~ 150 | 0,79 * (p+1) |

SPF-16-20 | SPF-16-21Y | ~ 330 | 1,19 * (p+1) |

SPF-20-29 | - | ~ 660 | 1,86 * (p+1) |

Most important for the right choice of insert size is the specific required interlace performance.

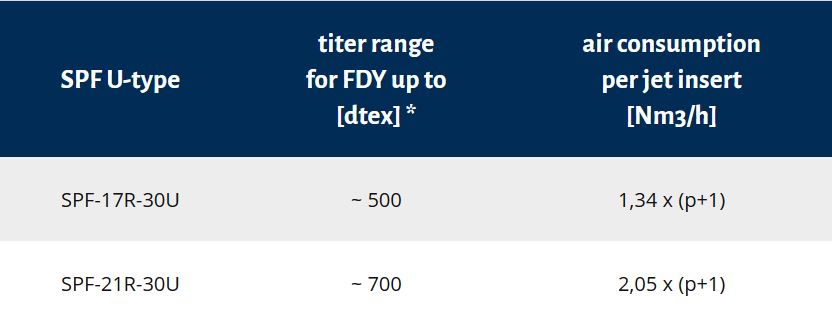

SPF U-type | titer range

for FDY up to

[dtex] * | air consumption

per jet insert

[Nm3/h] |

|---|---|---|

SPF-17R-30U | ~ 500 | 1,34 x (p+1) |

SPF-21R-30U | ~ 700 | 2,05 x (p+1) |

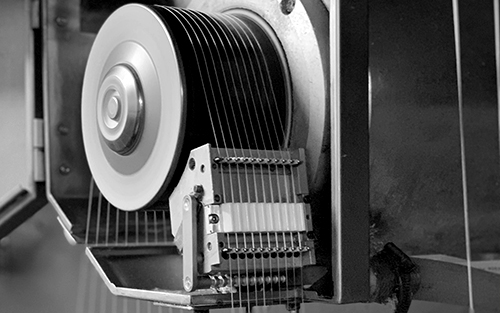

SPF interlacing jets

SPF jet, single

SPF jet, twin

SPF technology

The design enables the application of single jets, as well as multi thread jets, to all conceivable numbers of thread lines and yarn end separations.

The easy quick exchange system of the jet inserts allows a simple and safe maintenance.

The sophisticated geometry and surface character within the interlacing zone guarantee an excellent interlacing performance concerning the high requirement of the composed knot regularity.

Most important for the right choice of insert size is the specific required interlace performance.

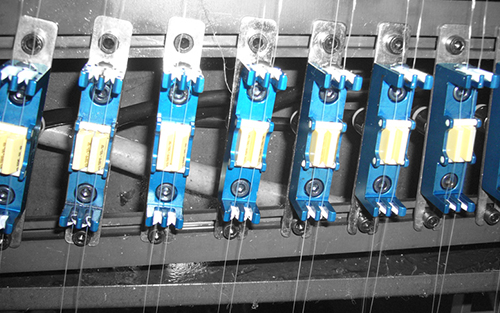

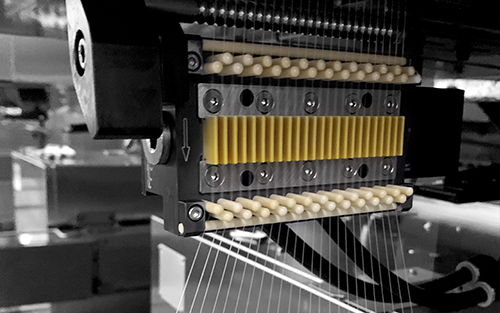

SPO block jets

The SPO block jets are based on the approved and established SPF jet technology.

The design has been made in accordance to the new developments in textile spinning machinery, enabling its use as multi thread jets for all conceivable number of threads and yarn end separations.

The SPO block jets are equipped with a threading device for easy and safe threading. The shape of the jet inserts allows smooth threading without the yarn being pushed into the jet insert channel.

The sophisticated geometry and surface character within the interlacing zone guarantee an excellent interlacing performance concerning the high requirement of the composed knot regularity.

24-thread SPO jet

32-thread SPO jet

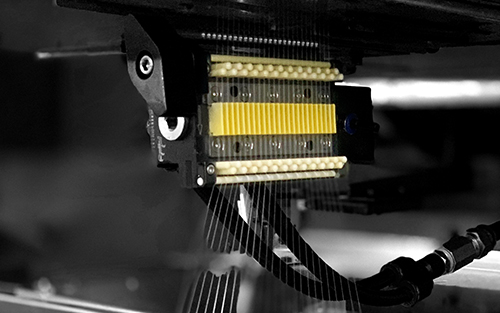

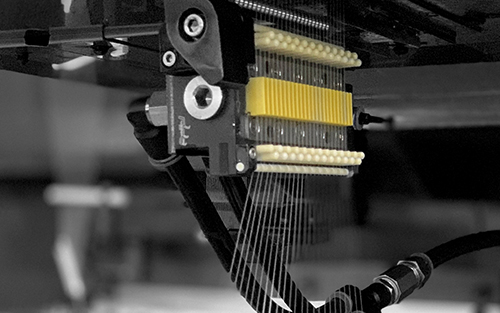

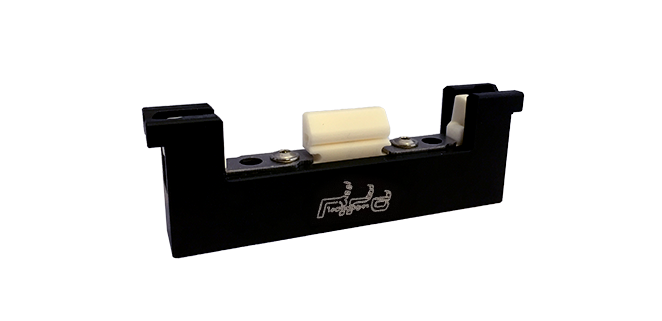

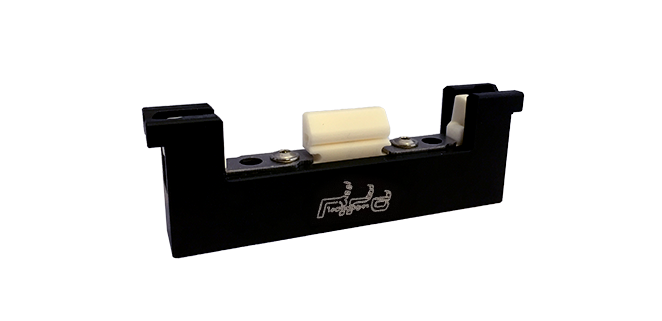

SPC interlacing jets

SPC technology

The design of the SPC jets is reduced to the essentials, enabling its use as single as well as multi thread jets for all conceivable numbers of threads and yarn end separations.

The unique yarn guiding system and the sophisticated geometry within the interlacing zone ensure an excellent interlacing performance.

The SPC jets are also used for pre-interlacing as well as migration applications in FDY spinning processes.

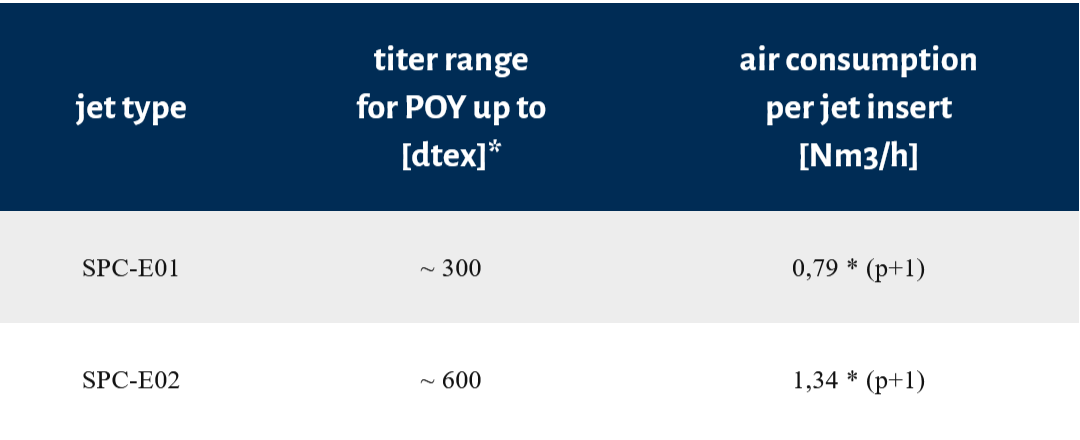

jet type | titer range for POY up to [dtex]* | air consumption per jet insert [Nm3/h] |

|---|---|---|

SPC-E01 | ~ 300 | 0,79 * (p+1) |

SPC-E02 | ~ 600 | 1,34 * (p+1) |

Most important for the right choice of insert size is the specific required interlace performance.

SPC jet

SPC jet

with yarn guide protection

SPC-E01-1-11-02

SPC interlacing jets

SPC jet

SPC jet

with yarn guide protection

SPC-E01-1-11-02

SPC technology

The design of the SPC jets is reduced to the essentials, enabling its use as single as well as multi thread jets for all conceivable numbers of threads and yarn end separations.

The unique yarn guiding system and the sophisticated geometry within the interlacing zone ensure an excellent interlacing performance.

The SPC jets are also used for pre-interlacing as well as migration applications in FDY spinning processes.

Most important for the right choice of insert size is the specific required interlace performance.